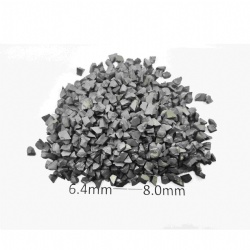

YG8 crushed tungsten carbide grit 5-80 mesh crushed carbide grit agriculture usage crushed carbide grit

Tungsten carbide grit is the material applied to components of applications with a high level of abrasion. Through hardfacing, tungsten carbide grit can be applied to a new part in order to better its wear resistance or to a used part to restore its worn-down surface.

Grit is used for long lasting wear protection in areas of high abrasive wear. It is used to keep costly parts – bulldozer blades, wood grinding tips, trencher teeth, and bucket teeth – from wearing down quickly. Using tungsten carbide grit on machinery parts that see a lot of wear and tear significantly extends the life of those parts. For this reason it is used in many different applications including woodwaste, agriculture, wear parts, plow attachments, and drilling. Grit adds an extra layer of protection to costly parts, increasing efficiency and decreasing downtime.

|

Size/inch |

Size/mm |

|

1/32"~1/16" |

0.79-1.59mm |

|

1/16"~1/8" |

1.59-3.175mm |

|

1/8"~3/16" |

3.175-4.76mm |

|

3/16"~1/4" |

4.76-6.35mm |

|

1/4"~5/16" |

6.35-7.94mm |

|

5/16"~3/8" |

7.94-9.53mm |

|

3/8"~1/2" |

9.53-12.7mm |

|

|

Grade |

Component |

|

|

YG |

Crushed tungsten carbide granule, containing 6-11% cobalt and 89-94% tungsten carbide. The hardness is HRA89.8, the density of 14.4-14.8g/cm3.

|

|

|

YN |

Shaped polyhedral tungsten carbide particles, containing nickel 6-10%, tungsten carbide 90-94%, The hardness is HRA89, the density 14.6-14.8 g/cm3. It is non-magnetic or weak magnetic, corrosion resistance.

|

|

|

YM |

Crushed tungsten carbide granule, containing 5.3-9.3% cobalt, 50-75% tungsten carbide and 15-40% titanium carbide. The hardness is HRA91, the density of 11.5-13g/cm3. |

Q1. Are you a manufacturer?

A: Yes, we are. We have the best factory to produce for you,could guarantee the price is the most competitive.

Q2. What is your terms of payment?

A: T/T 50% as deposit, and 50% balance before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3.Could you offer OEM and ODM service?

A:That is ok ,we have more than 5 years experience in OEM service.professional R&D department is ready to design products to fit your specifications,they can offer the professional advice and CAD drawings(3D) for you!

Q4. How about your delivery time?

A: Lead time as fast as 7-15 days!

Q5. What is the MOQ ?

A.No MOQ for our existing stock,for special size,MOQ is 5 KGS.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.Our production is based on ISO9001,we have more than 10 years experience of QC team and strictly quality control system in our production process.

Q8. What about the package?

A.It can make as the you need and depend on the products shapes. Generally, we can provide iron drum, carton, wooden case, and bag packages.

Q9: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.